قالب برای قطعات لوله کشی تامین آب

Mold for Water Supply Piping Components Molds for water supply piping components are critical tools in the manufacturing of plumbing systems, ensuring the production of high-quality, durable, and leak-proof parts. These molds are designed to create components such as fittings, valves, connectors, and joints, which are essential for efficient water distribution in residential, commercial, and industrial applications. Material and Design Considerations The molds are typically made from high-grade steel or aluminum to withstand high pressure and temperature during the injection molding process. The choice of material depends on factors like production volume, component complexity, and cost efficiency. Steel molds offer superior durability for large-scale production, while aluminum molds are lighter and more cost-effective for prototyping or smaller batches. Precision is paramount in mold design to ensure dimensional accuracy and smooth surface finishes. Advanced CAD/CAM software is used to create detailed 3D models, optimizing the mold for manufacturability. Features like cooling channels, ejector pins, and venting systems are integrated to enhance cycle times and minimize defects such as warping or air traps. Manufacturing Process Injection molding is the most common method for producing plastic piping components. Thermoplastics like PVC, CPVC, PEX, and PP are melted and injected into the mold cavity under high pressure. The material cools and solidifies, taking the shape of the mold before being ejected. For metal components, die-casting or forging may be used, requiring molds with higher heat resistance. Quality and Performance The mold must produce parts that meet stringent industry standards for pressure resistance, corrosion resistance, and longevity. Tight tolerances ensure proper sealing and compatibility with other piping systems. Post-molding processes, such as deburring or surface treatment, may be applied to enhance functionality. Innovation and Sustainability Modern molds incorporate innovations like multi-cavity designs to increase production efficiency and reduce material waste. Sustainable practices, such as using recycled plastics or energy-efficient molding machines, are also gaining traction. In summary, molds for water supply piping components play a vital role in delivering reliable, efficient, and safe plumbing solutions. Their design, material selection, and manufacturing precision directly impact the performance and longevity of the final products.

تولید - محصول

طبقه بندی:

-

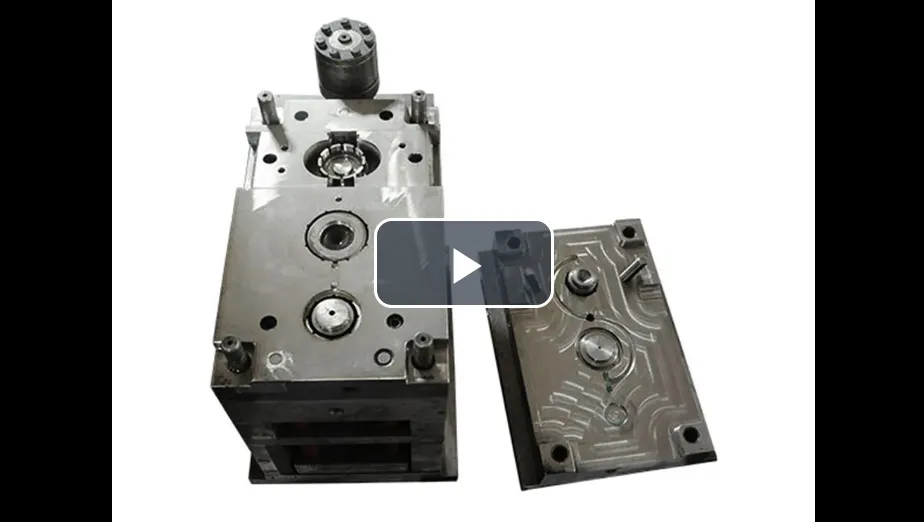

قالب اتصال لوله دسته شیر پی وی سی

دسته بندی: قالب اتصالات سوپاپ توپبازدیدها: 578شماره سریال:زمان انتشار: 2025-09-17 00:24:22قالب اتصال لوله دسته شیر پی وی سینام قالب:قالب اتصال لوله دسته شیر پی وی سیحفره: 8 حفرهاندازه قالب: 50 میلی مترفولاد قالب: 2738 یا 718 برای حفره و هستهدروازه: دروازه مستقیمساختار قالب: قطب بالا بیرون زدهسختی هسته / حفره: HRC 38-42 درجه پس از عملیات حرارتی خلاءدستگاه قالب گیری تزریقی: 180 T Taizhou Huangyan Hong Jin mold Co., Ltd در سال 2002 تاسیس شد. ما بیش از 23 سال در طراحی و ساخت قالب اتصالات لوله حرفه ای هستیم.ما مشتاقانه منتظر همکاری طولانی با شما هستیم.در زیر اطلاعات اصلی برای مرجع شما آمده است.سوالات متداول:1. MOQ شما چیست؟1 مجموعه اوکی است2. زمان تحویل شما چقدر است؟زمان تحویل حدود 60...

اخبار

طبقه بندی:

-

[industry news]عوامل زیر در فرآوری قالب های تزریقی موثر هستند

2024-09-06 16:57:27

مورد

طبقه بندی:

ویدئو

طبقه بندی:

دانلود

طبقه بندی:

هنوز هیچ نتیجه جستجویی وجود ندارد!

استخدام

طبقه بندی:

هنوز هیچ نتیجه جستجویی وجود ندارد!

محصولات پیشنهادی

هنوز هیچ نتیجه جستجویی وجود ندارد!

واتساپ

واتساپ تلفن

تلفن